Download the Latest ON-GUARD Case Study

Learn how this 24-Hour Biomass facility used precision lubrication injections with the ON-GUARD in conjunction with their online vibration monitoring system to safely extend this functionally failed bearings life until the next planned shutdown.

ON-GUARD's Embedded Software

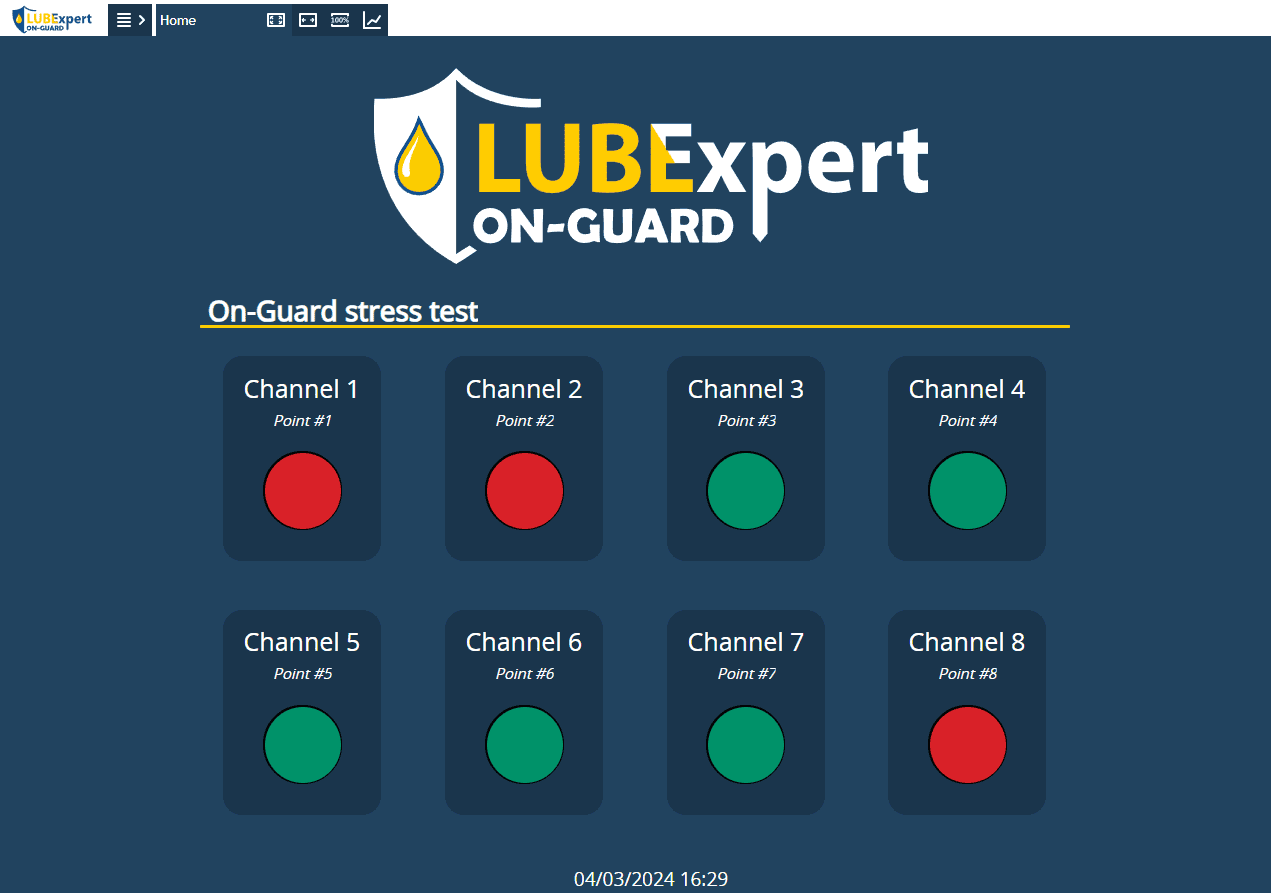

Asset Stress Test

Gain a comprehensive view of your system at a glance with the ON-GUARD Stress Test Snapshot.

Enjoy the peace of mind that comes with ON-GUARD's blend of automation, precision measurements, and patented data-driven decision making.

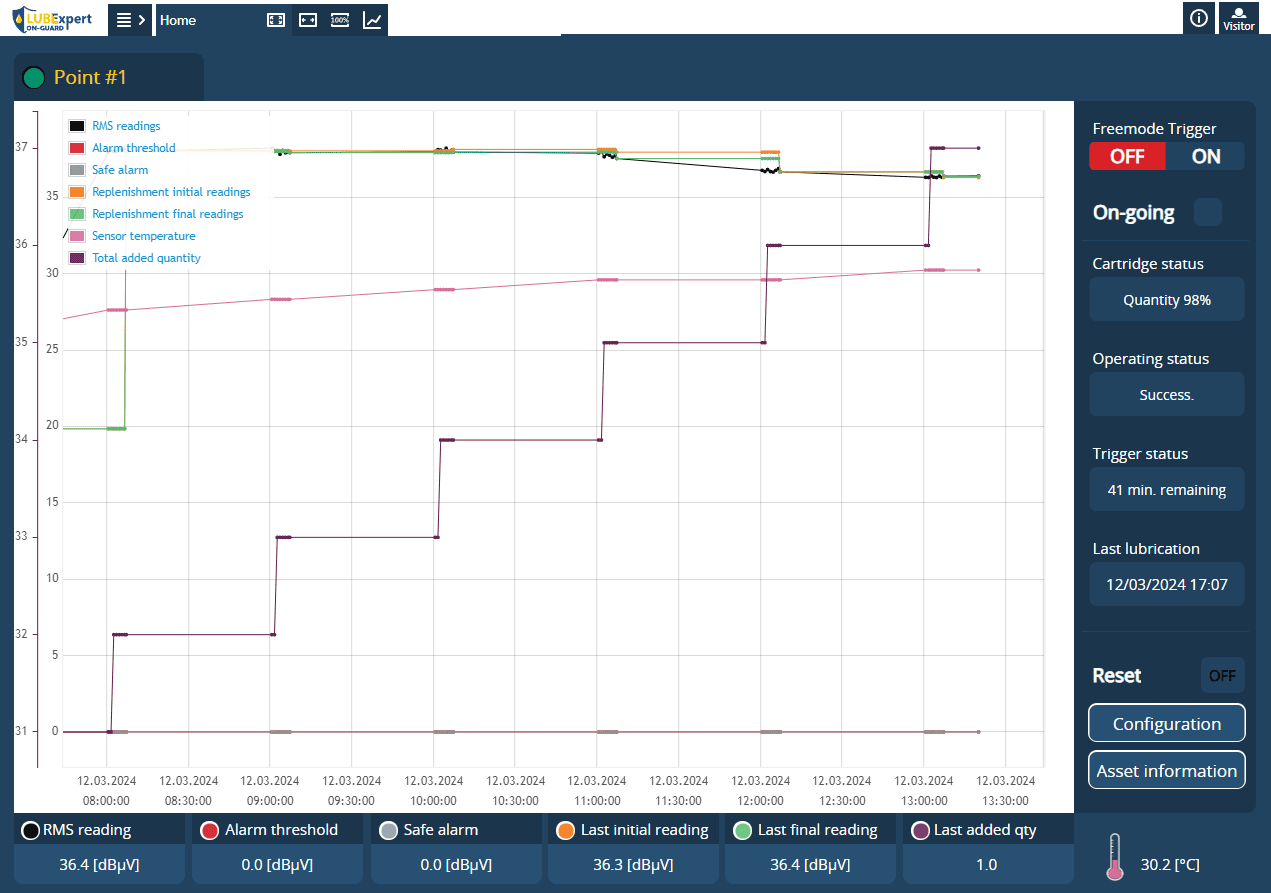

Trending Lubrication Data

Operators can view the entire process from the convenience of their web browser, no matter their current whereabouts.

Continuously monitor friction levels & a number of other parameters from the integrated browser-based dashboard.

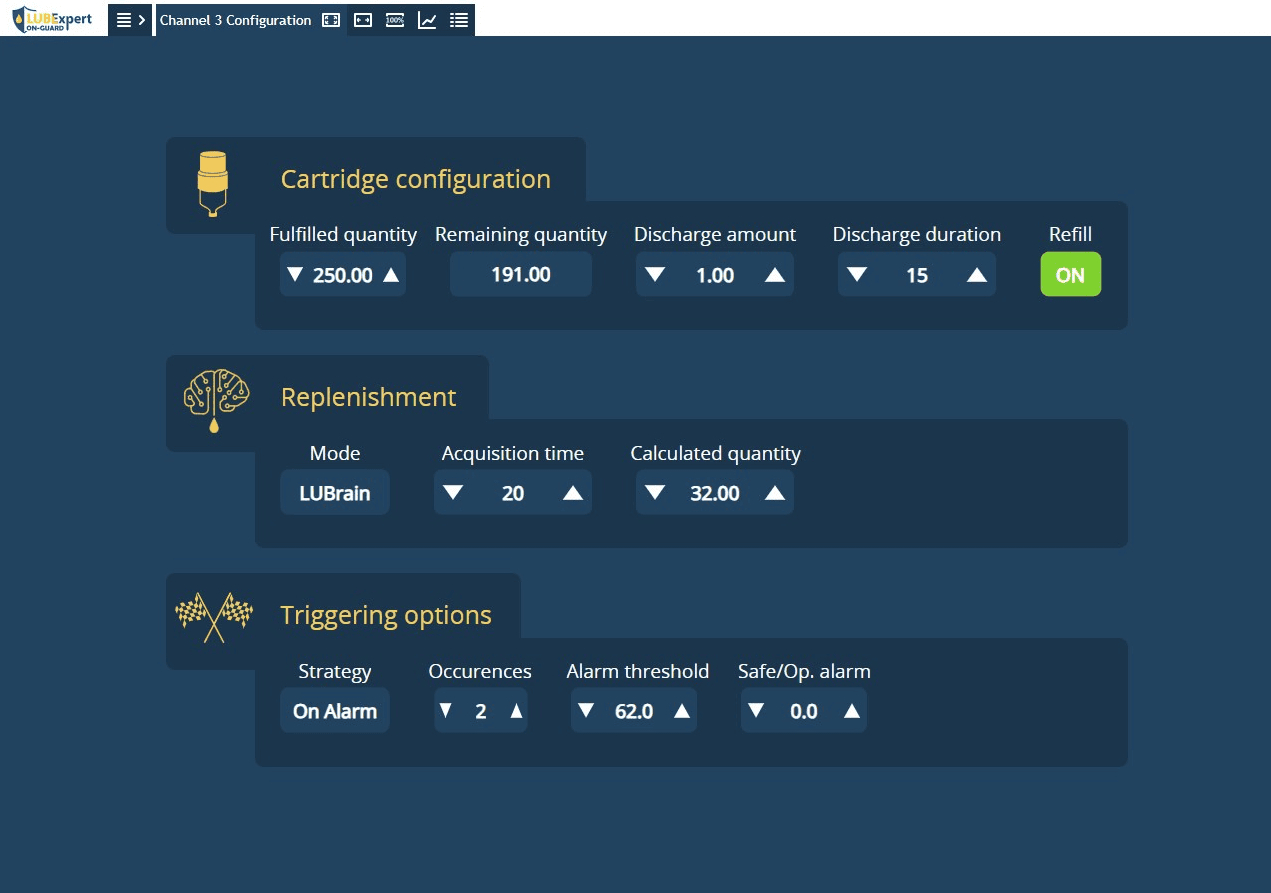

Custom System Configuration

Configure your system to your assets and organization.

Fully customize cartridge size, injection quantity & speed, measurement acquisition mode (Manual or LUBrain) & time. Triggering options can also specify alarms & the amount of time an asset must spend in alarm before an injection is triggered.

Why SDT... Why Ultrasound?

For millennia, humans relied upon a keen sense of hearing to alert us of danger, and today that same attribute warns us when our assets are about to fail. The earliest indicator of a change in an asset’s condition are in the ultrasonic domain, no matter how subtle those changes might be. Ultrasound senses micro-sonic changes in an assets function, allowing us to anticipate failure and plan maintenance.

At SDT Ultrasound Solutions, we enable our customers to achieve their operational objectives by improving the reliability of their assets. We have supported industry with our advanced ultrasound solutions for nearly 50 years; Promoting more reliable, sustainable, and safe manufacturing processes and empowering maintenance and reliability teams to better understand the health of their most critical production assets.